Headbox

Most crucial component of a wetlaid nonwoven production line

KM AQUAFORMER

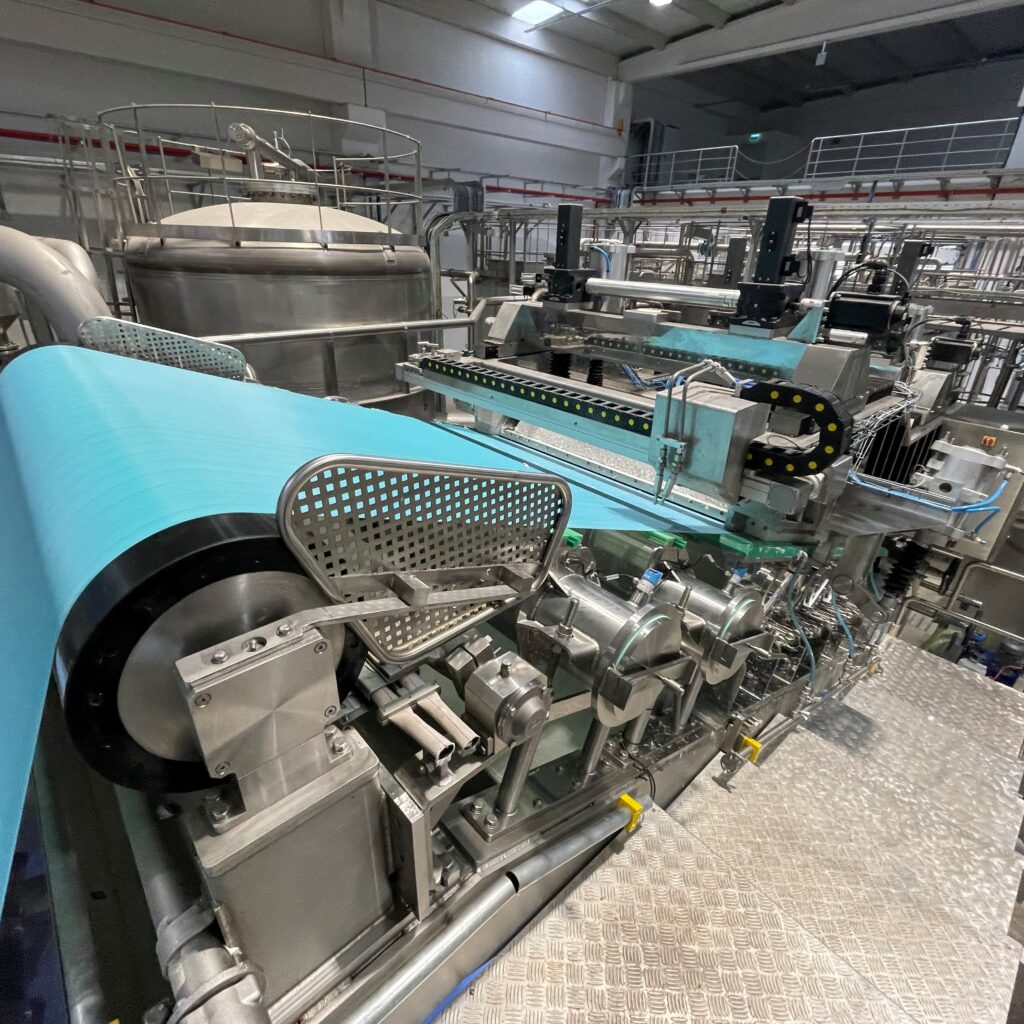

KM-AquaFormer is the most crucial component of a wetlaid production line. It performs the entire wet laying steps. Wet laying is a mature and the most effective method that has been used in paper and wetlaid nonwoven industries for quite some time. This method allows the production of nonwoven materials from renewable and cost-effective, eco-friendly fibers like cellulose and pulp.

Wet former’s process flow is as follows:

- Water with fibers in suspension from the white water tank is pumped to the headbox.

- Fibers are laid on the mesh belt under the headbox. An inclined headbox design is used for fiber distribution and spacing to be homogenous and consecutive. The dilution ratio of fibers in water is very critical and needs to be adjusted optimally. The ratio changes based on the fiber type and fiber lengths.

- The pumping and flow pressure must be stable to ensure a constant flow of fibers on the mesh belt. The water gets through the mesh and is sucked while the fibers stay atop and form the web.

- The main goal is to have a very uniform web formation with desired porosity through a perfect fiber distribution where each fiber lands right next to the other without so much overlapping or hindrance.

- The excess water then is recycled back to the white water tank for cost and energy saving.

Main Benefits

KM-Aquaformer makes sure the best and the most efficient wet laying solution for your needs.

The easy and single production process of NW materials made of multiple fiber types

Typical Applications

General Purpose

Personal Care

Adult Wipes

Pet Care Wipes

Household

Skin Care

We are passing through times of high environmental awareness, debates are going on about the ban of plastics at many levels. On the other hand, humankind is polluting the environment at an exponentially increasing pace. The convenience and availability of one-time-use products and especially wipes are causing a lot many issues in sewage systems and creating blockages. Therefore the flushability, dispersibility and biodegradability have become the main focus of the hygiene industry, especially in wipes, more specifically wet toilet wipes or wet toilet tissues.

Thanks to the newest wetlaid and spunlace technologies, flushable wipes are available with proper strength.

KM-Aquaformer systems are equipped with all necessary features to produce wipes materials according to the latest flushability guidelines.

Wet laying and spun lacing can also be used in the same production process to produce carded + pulp nonwoven materials. These materials can be made of 100% natural fibers. Adding viscose and cotton fibers in the wet laying process, sustainable, eco-friendly and biodegradable nonwovens can be produced.

200 m/min Mechanical Speed

Final Product: NW fabric for flushable wipes material, Glass Fiber Mats, Carbon Fiber Mats Wood pulp (75 – 85%) + made of man-made fibers of max 16 mm fiber length (15 -25 %)

Process Fibers: Wood pulp, short-cut cellulosic staple fibers such as viscose, lyocell, carbon fibers, glass fibers

* The production capacity of the proposed equipment depends on the production parameters such as: fineness and nature of the fibres, product width, weight in g/m² and draft in the line under different working conditions. Production and performance levels are influenced by factors out of the control of the machine manufacturer, such as the fibre selection, the environmental conditions (humidity, temperature …), the experience, training and skill of the operators, and correct settings for each product. All information is given in metric units.

| Production Capacity* | 1750 mm – All values are given at winder | |||

| Basis weight (g/m²) | 40 | 50 | 65 | 80 |

| Speed (m/min) | 200 | 200 | 170 | 110 |

| Capacity (t/h) | 0,741 | 0,927 | 1,025 | 0,815 |

| Reference Product | Single layer wipe – 65 gsm | |||

| Production Capacity* | 3750 mm – All values are given at winder | |||

| Basis weight (g/m²) | 40 | 50 | 65 | 80 |

| Speed (m/min) | 200 | 200 | 170 | 110 |

| Capacity (t/h) | 1,728 | 2,16 | 2,386 | 1,9 |

| Reference Product | Single layer wipe – 65 gsm | |||

Service Voltage 400 V +/- 5%, Control Voltage 230 V AC; 24 V DC, Frequency 50 Hz ± 1%, Switch Cabinet Light 230 V AC